-

Pipes & Tubes

-

Pipe Fittings

-

Flanges

-

Round Bar & rods

-

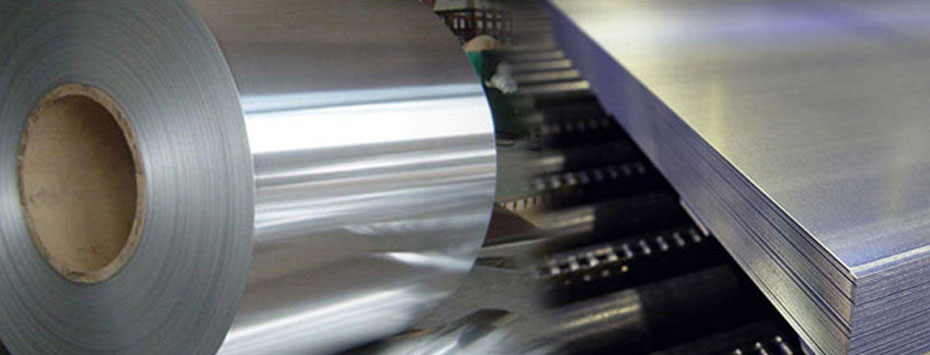

Sheets & Plates

Stock Sizes: Lengths ranging from 12'- 28' Custom sizes available

Machining: Stainless Steel 630 ph delivers an excellent combination of good oxidation and corrosion resistance, high strength, good toughness in both the welds and base metal, and good quality mechanical properties at temperatures up to 600 degrees Fahrenheit. Engineers and designers frequently choose Stainless Steel 630 due to its high strength as well as its superior corrosion resistance when compared to many other high strength Stainless Steels. Primary Elements: Stainless Steel 630 are alloys primarily comprised of 17 percent Chromium, 4 percent Nickel, 4 percent Copper, with the balance being Iron, along with trace amounts of Manganese, Phosphorus, Sulfur, Silicon, Columbium and Tantalum. Features: Stainless Steel 630 is classified as a precipitation hardened steel. Stainless Steel 17-4 ph can be forged, welded and formed. Machining is performed in the solution-annealed state, followed by precipitation hardening. While the hardening occurs over a range of temperatures, ductility and strength can be adjusted to achieve a range of mechanical properties. Bar Types Available: • Round stainless steel bar• Flat stainless steel bar (H.A.R.P.) • Nickel pump shaft • Stainless hexagon bar Industries Served: • Petrochemical • Food processing • Aerospace • Cemical • Paper • Petroleum • Metalworking Industries Products constructed of 15-5 Stainless Steel Bar:

Specifications :- Grades : Elimination of silica CaO (s) + SiO2 (s) → CaSiO3 (l) Elimination of phosphorus 3 CaO (s) + P4O10 (s) → Ca23(PO4) 2 (l)

• Cutting • Bending • Forging • Rolling • Heat Treatment • Minor Fabrication  |